When it comes to car-related content, many people only know about the brand name, and those who really understand the car are often car professionals. New energy electric vehicles are now a hot word in the automotive industry. Because of their short appearance, many people still don’t know them well. Then, we will introduce you to the knowledge of high voltage interlocks in new energy vehicles,and the role of HVIL connector.

From the perspective of system functional safety, every possible risk must be monitored by corresponding safety technical means to reduce the probability of risk occurrence. From this level, high-voltage interlocks are used in circuit design as a safety measure for the safety of automotive high-voltage systems.

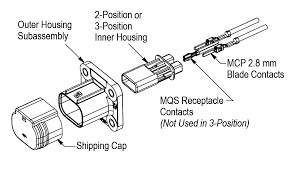

HVIL is the abbreviation for high voltage interlock loop. Also called Hazardous Voltage Interlock Loop,high-voltage interlocking refers to the use of low-voltage signals to check all the shunts connected to the high-voltage bus on the electric vehicle, including the entire battery system, wires, connectors, DCDC, motor controllers, and high-voltage boxes Integrity and continuity of electrical connection of system circuits such as protective covers.The power battery pack is used as the power supply in the high-voltage circuit, and the low-voltage circuit also needs a power supply for detection to transmit the low-voltage signal along the closed low-voltage circuit. Once the low-voltage signal is interrupted, it means that a certain high-voltage connector is loose or disconnected.

In general, the design of high voltage interlock loop for electric vehicles must follow the following principles:

- The HVIL must be able to effectively, real-time and continuously monitor the on/off status of the entire high-voltage circuit;

2. All high-voltage connectors should be equipped with mechanical interlocking devices, and the connectors can only be connected after the HVIL circuit is disconnected first;

3. All high-voltage connectors cannot be connected or disconnected under non-human conditions;

4. The HVIL circuit should be equipped. Under certain special circumstances, the HVIL circuit can be directly detected through the BMS and the high-voltage circuit can be directly disconnected;

5. Regardless of the state of the electric vehicle, when HVIL recognizes a danger, the vehicle must give an alarm to the dangerous situation, and the instrument or indicator needs to alert the driver in the form of sound or light alarm.

Since the electric vehicle power system is composed of multiple subsystems, they are connected to each other by high-voltage connectors, and the operating environment at the same time is very harsh. Most of the working conditions are under vibration and shock conditions, so high-voltage interlocking Design is the key to ensuring the safety of personnel and the safe operation of vehicle equipment.

Elecbee is an online market for electronic parts, all of which come from the most competitive factories in China. If you have any questions about the principle of high voltage interlock loop technology, or if you need to order connectors, you can contact us at any time, or leave your email address, we will reply to you in time.